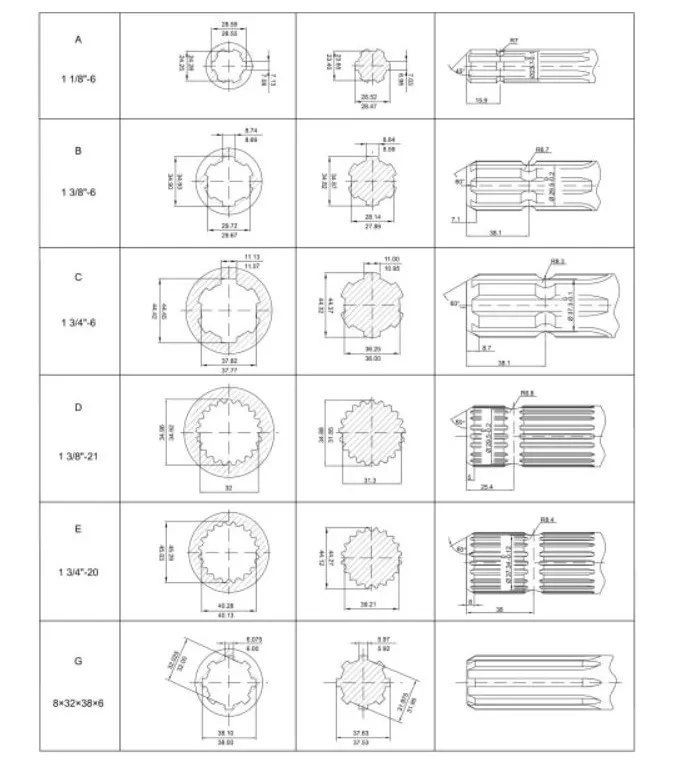

Pto Spline Shaft Cardan Splined Shape Tractor Flexible

As one of the tractor shaft manufacturers, suppliers, and exporters of mechanical products, We offer tractor shafts and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of tractor shaft.

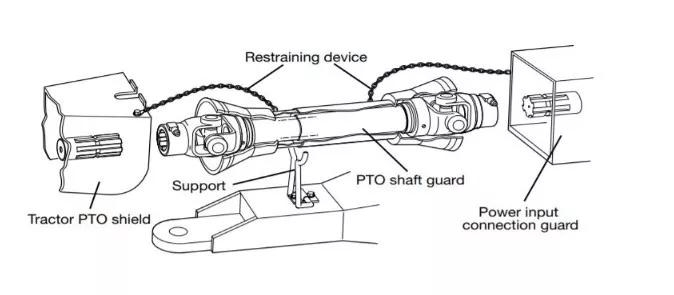

Complete Driveline with Quick Disconnect Yokes.

Collapsed Length: 48″ (1230 mm).

sufficient overlap of the drive tubes exists in all working positions without the possibility of bottoming out.

How Do PTO Shafts Work?

A PTO shaft works by tapping energy from the tractor’s engine. This energy is then transferred to a hydraulic pump, which then builds pressure and moves hydraulic fluid. This movement, in turn, moves energy from the tractor’s engine to the implement. A power takeoff shaft is more effective in larger tractors.

PTOs can rotate in either direction, either clockwise or counterclockwise. It is important to note that the direction of rotation should be standardized. This is so that any damage that can occur is minimized. If the rotation direction is distorted, the PTO can cause damage to the implements it is attached to. For this reason, PTOs should not be used in reverse for too long.

Manufacturing Plant

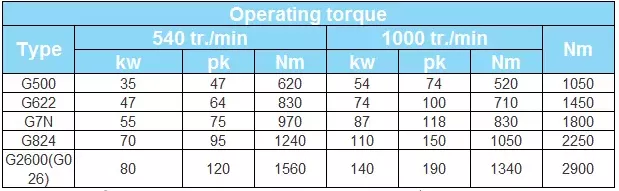

Scope of Application

Packing&Delivery