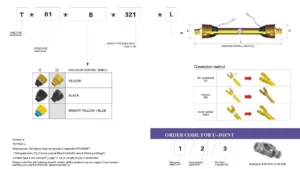

Forged Tractor Pto Shaft For Agricultural Machinery

As one of the tractor shaft manufacturers, suppliers, and exporters of mechanical products, We offer tractor shafts and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of tractor shaft.

Rough Forgings

All yokes are made of high-quality steel by forging. They have a much longer life span than casted yokes.

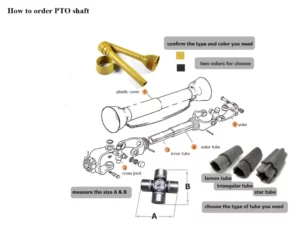

Customized plastic cover

New plastic material, High breaking strength, resistance to low-temperature -20℃, color and printing customized.

Easy to lubricate

The lubricating nipple is protected during painting to make it clear.

Protection for your engine

The shear bolt of the torque limiter is tested according to the required torque.

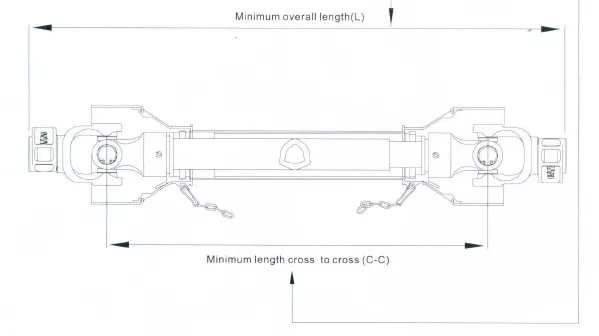

How Do PTO Shafts Work?

A PTO shaft works by tapping energy from the tractor’s engine. This energy is then transferred to a hydraulic pump, which then builds pressure and moves hydraulic fluid. This movement, in turn, moves energy from the tractor’s engine to the implement. A power takeoff shaft is more effective in larger tractors.

PTOs can rotate in either direction, either clockwise or counterclockwise. It is important to note that the direction of rotation should be standardized. This is so that any damage that can occur is minimized. If the rotation direction is distorted, the PTO can cause damage to the implements it is attached to. For this reason, PTOs should not be used in reverse for too long.

Manufacturing Plant

Scope of Application

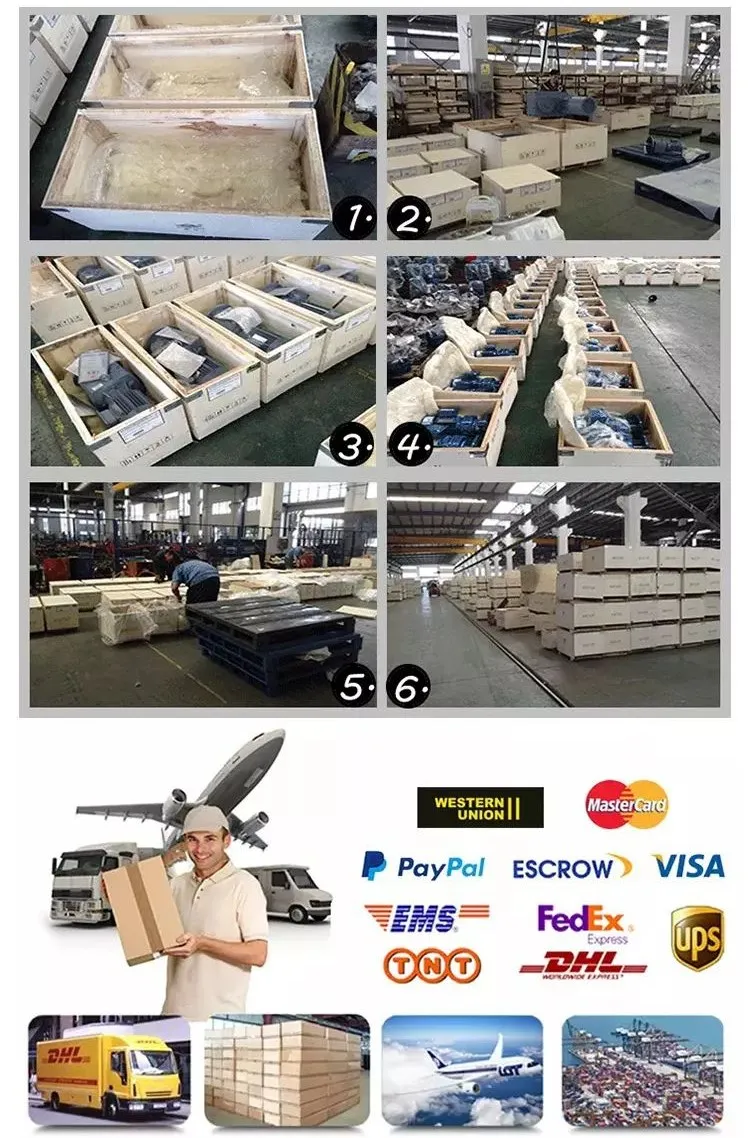

Packing&Delivery